QC 500 - Quality Control

Helps you maintain consistent product quality by adjusting densities based on sampling data

- Maximize quality with QC Control

- Comprehensive documentation and reporting

- Intuitive and user-friendly interface

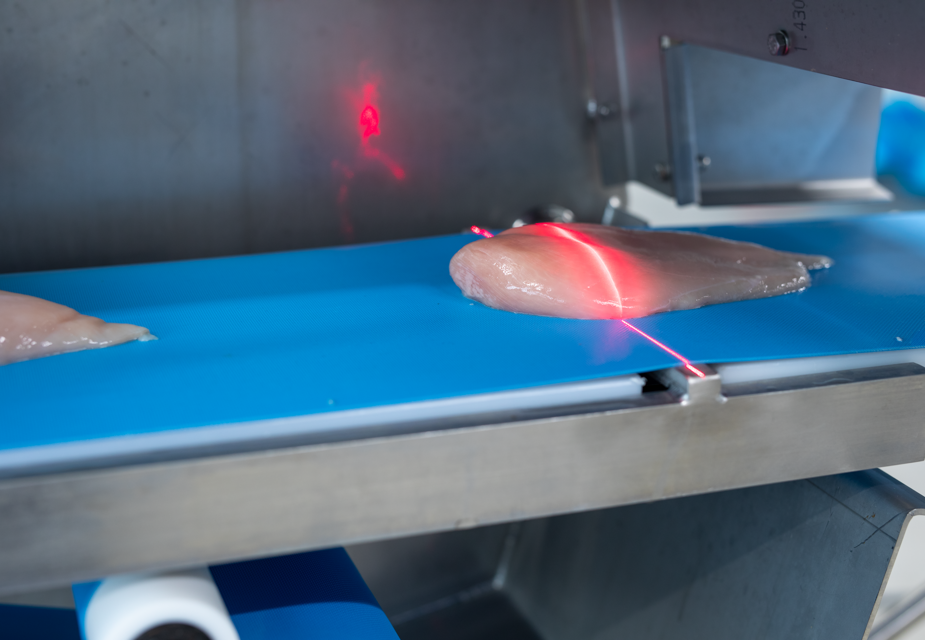

Ensuring consistency and food safety — every cut, every time

Automated density adjustment – enhances portioning accuracy by calibrating product densities based on real-time sampling data, ensuring consistent product weight.

Seamless integration with portion cutters – works in sync with Borncut portion cutters, automatically adjusting product weight and density to maintain precision.

Comprehensive QC reporting – generates detailed reports for traceability, compliance, and quality assurance, meeting industry regulations effortlessly.

User-friendly multi-touch interface – simplifies operation with an intuitive interface for quick product specification input and one-click application changes.

Visual product preview for setup – displays cutting patterns and expected yields, aiding in accurate setup and minimizing errors.

Real-time quality sampling – uses static or dynamic weighing systems to analyse and adjust portioning based on actual vs. Target weights.

Raw material quality and food safety – ensures consistent raw material quality by monitoring weight variations and detecting irregularities, helping maintain food safety.

Optimized production efficiency – minimizes waste and maximizes yield by continuously fine-tuning portion accuracy and ensuring consistent product quality.